Follow my process

Start from an idea, proceed with design, continue with stitching, assemble the pieces, and quality check. Restart if needed!

Inspiration

Love walking in nature and observing the small flowers, the grass, tree leaves, or small details that may get unnoticed.

Lately, I noticed the beautiful pattern of frosted leaves in my yard and felt determined to adopt the frosted leaves in one of my new designs. The idea though needs to mature, and take shape. In this case, It took me two weeks to start designing the pattern for this bracelet.

Assembling

The process of assembling all parts together needs patience and the findings reveal their quality at this point!

The final product must be flawless and beautiful and offer the highest possible quality to the customer.

Beads, what beads?

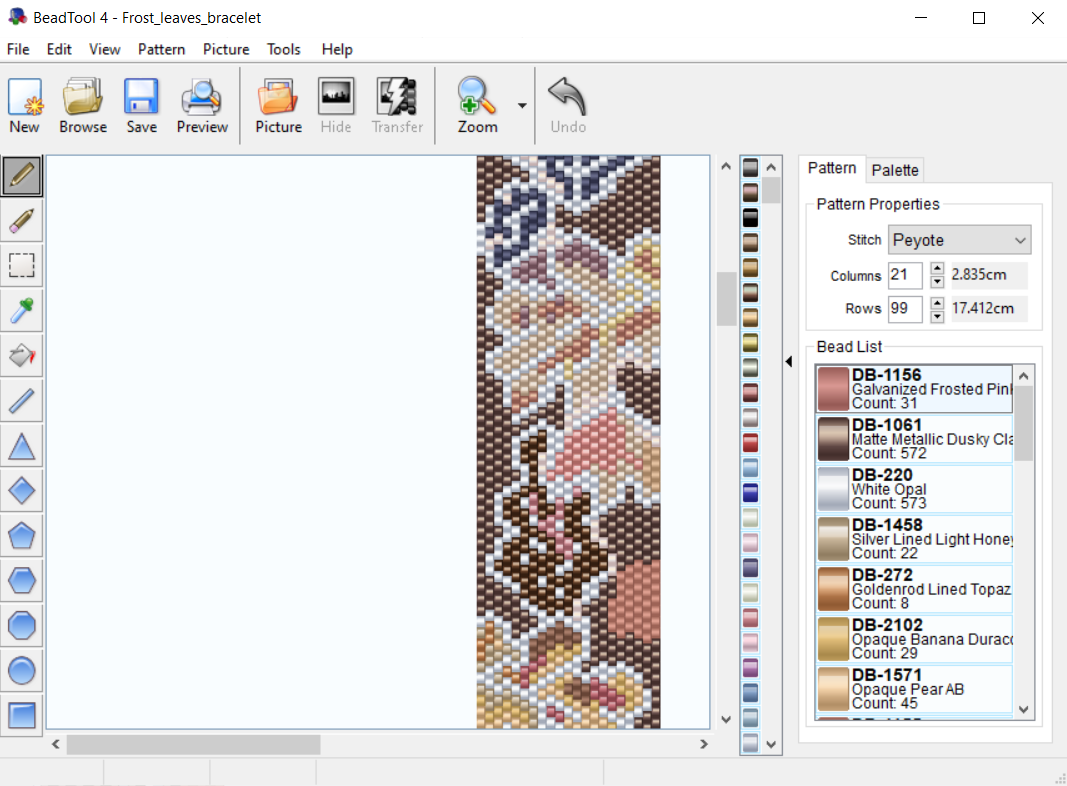

Design

I design my patterns using a specialised software that allows me to draw irregular shapes and choose the bead colours from my extensive bead stash.

For the first version of the pattern I usually use generic colours to draw the shapes and then I spend hours to explore the colour options and the finish of the beads that will bring into life my original idea.

I rarely finish a pattern in the course of a day. I revisit it to refine the colours and the shapes. When satisfied, I choose the colour of the thread and I start stitching.

Quality check

Every new design is thoroughly tested with exhaustive "test drives". I wear the prototype for days and treat it hard to test its endurance.

I use premium quality findings to ensure the pieces you buy will last for years and will retain their shape and shine.

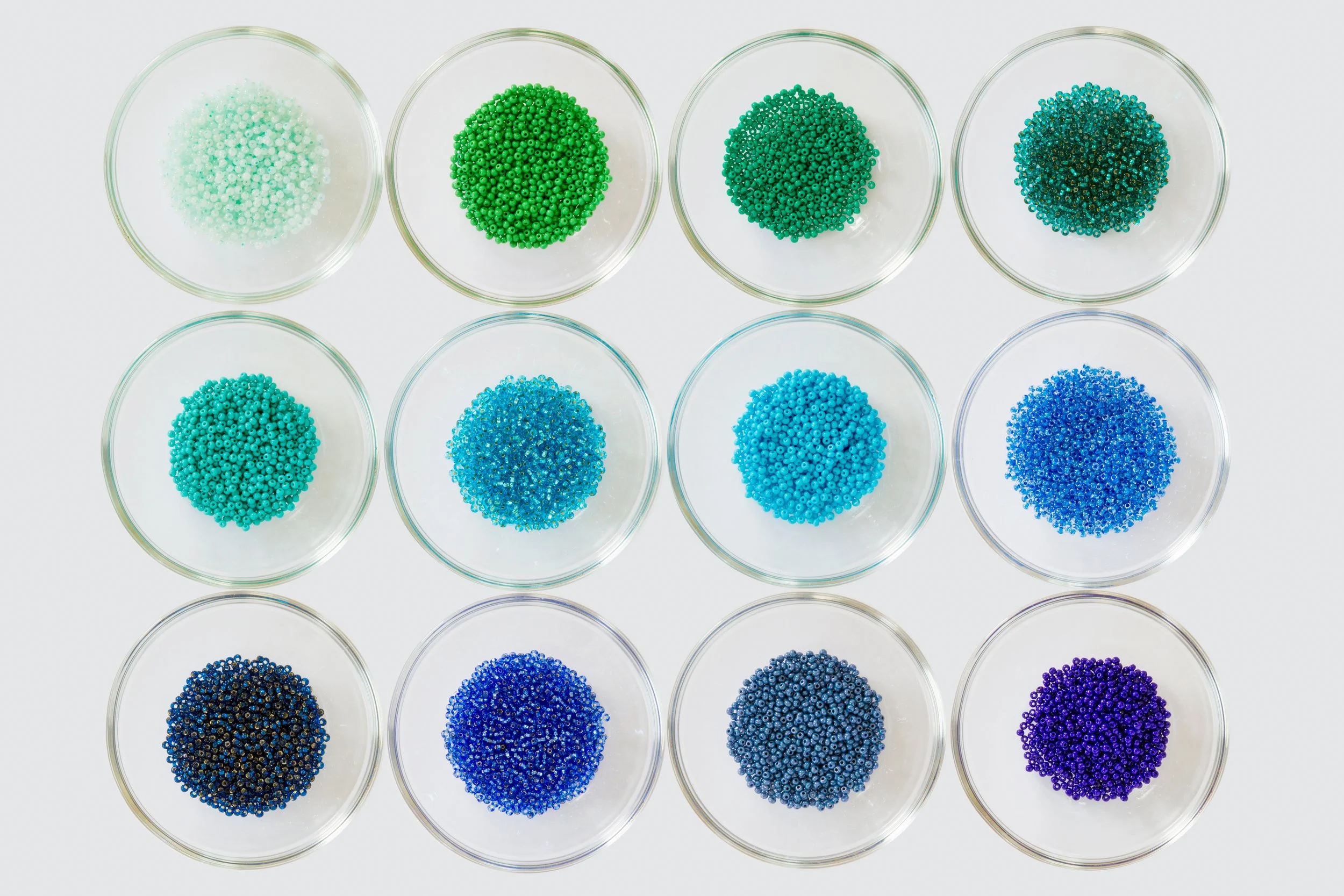

Throughout history, beads have been enchanting people from both Eastern and Western cultures. Artisans made beads in various shapes and sizes out of various materials. Glass however became an especially prized material for bead making due to its shimmering and glistening qualities. The Japanese production of glass seed beads began at mid-1930, Miyuki was founded in Hiroshima, and quickly became a renowned glass seed bead manufacturer offering premium quality glass beads. There are equally premium quality Czech glass beads. These premium glass beads are offered in thousand colours and finishes, sold per gram and in prices comparable to those of semi-precious stones.

Stitching

The size of the beads I am working with ranges from 1.3mm (0.051in) to 1.6mm (0.63in) with a hole of 0.65mm to 0.8mm. The needle and thread to stitch these beads into place are equally fine and delicate.

There are numerous techniques to stitch these beads. And as delicate and fragile a glass bead is as a unit, the stronger these become when stitched together. Strength lies in union as in the Aesopic fable! Any beadwork consists of several hundred up to several thousand beads.

Depending on the size and complexity of the pattern, stitching may last a couple of hours or a couple of months!

Restart if needed

Several times the result is not as expected and this may be due to factors such as poor colour/hue/finish bead choice, hasty stitching or improper findings.

When the final item does not match my original idea, my go-to choice is to restart from the very beginning, re-consider the shape, and select another colour pallette or a different bead finish.

All my items are made with premium quality glass beads, mainly Japanese Miyuki glass beads while sometimes I use Czech glass beads and crystals for details. Some of my designs include fine stones wire-wrapped to the beaded item.

The brands of glass beads and fine stones used in each design are listed in the description of each item in the shop.